Main characteristics and applications

Threading rolls and dies, cold extrusion tools, trimming, cutting and stamping tools for sheet thicknesses up to 6 mm, precision cutting tools for sheet

thicknesses up to 12 mm, cold pilger mandrels, circular-shear blades, deep-drawing tools, pressure pads and highly wear-resistant plastic moulds.

Comparable standards

| DIN | W.Nr | AFNOR | AISI/ASIM | JIS |

|---|

| X155CrVMo12-1 | 1.2379 | Z160CDV12 | D-2 | SKD11 |

|

Chemical composition (typical; in weight %)

| C | Si | Mn | P (max) | S (max) | Cr | Mo | V |

|---|

| 1.45-1.60 | 0.10-0.60 | 0.20-0.60 | 0.03 | 0.03 | 11.0-13.0 | 0.70-1.00 | 0.70-1.00 |

|

Physical properties (reference values)

| 20°C | 100°C | 250°C | 500°C | | Coefficient of thermal expansion at °C 10-6 m/(W/mk) | 10.5 | 11.5 | 11.9 | 12.2 |

|---|

| Thermal conductivity at °C (W/mk) | 16.7 | 20.5 | 24.2 | - |

|---|

Steel properties

12 % ledeburitic chromium steel. Combines maximum wear resistance, good toughness, outstanding cutting edge retention and tempering resistance.

It can be nitrided after special heat treatment.

Heat treatment

| TREATMENT | TEMPERATURE | HOLDING TIME (HT) | COOLING | HARDNESS |

|---|

| Annealing | Heat to 830 – 860 °C | Min. H.T. for 2 minute /mm | Furnace | - |

|---|

| Stress relieving | Heat to 650 – 700 °C | Min. H.T. for 2 minute /mm | furnace | - |

|---|

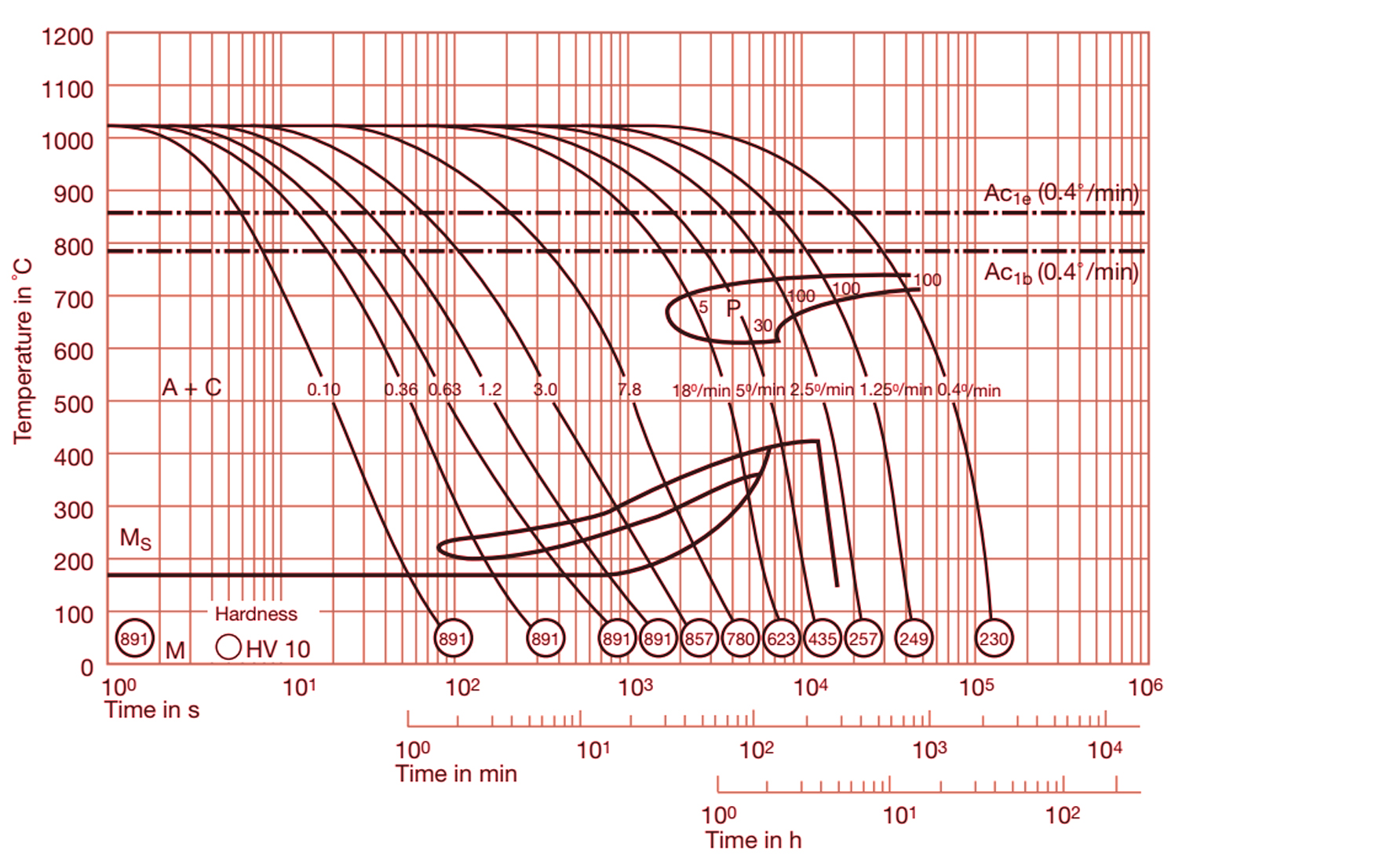

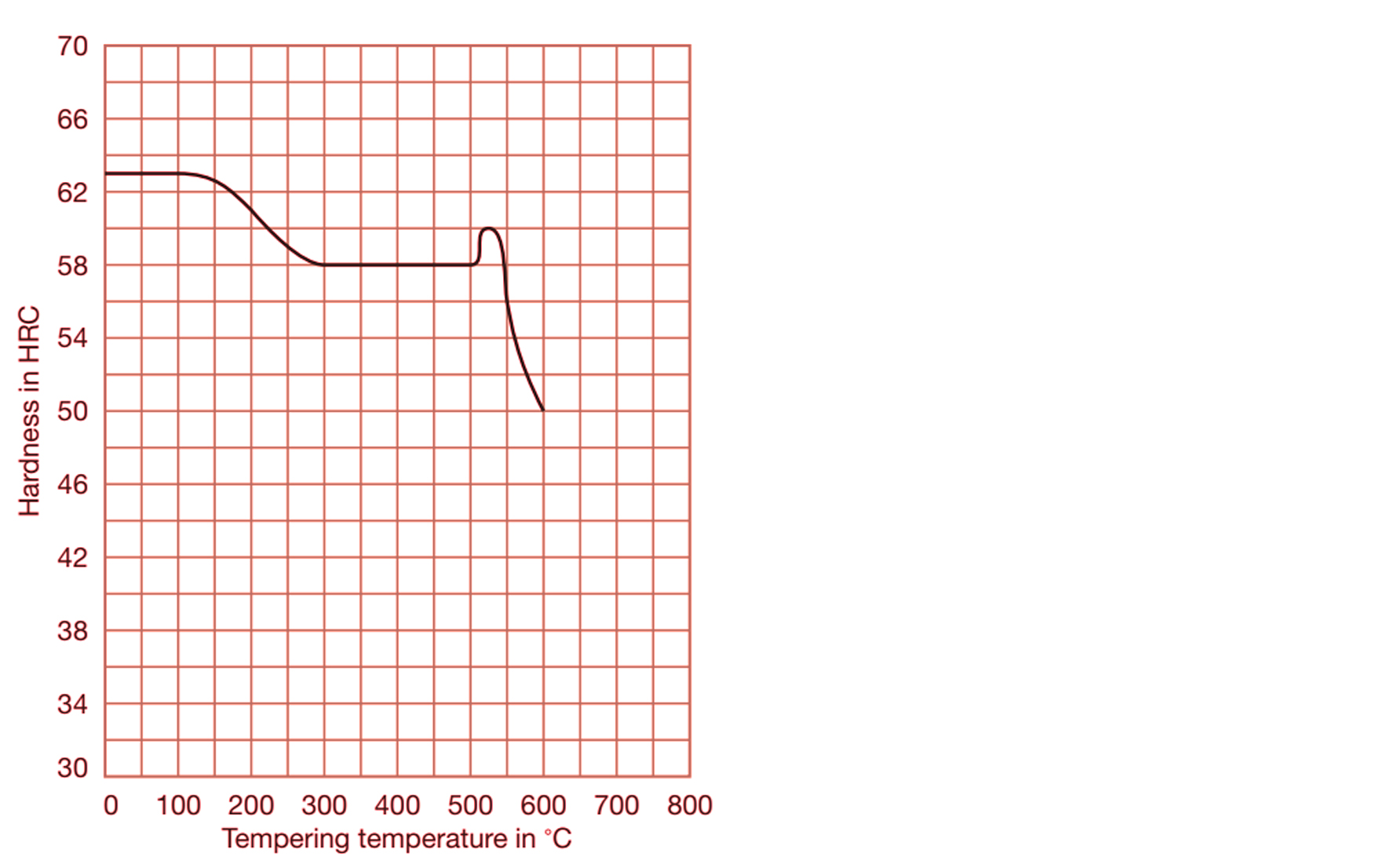

| Hardening | Heat to 1000 – 1050 °C | Min. H.T. for 1 minute /mm | Air, oil or saltbath, 500 – 550 °C | - |

|---|