Plastic product use has increased manifold. This has resulted in similar increase in use of steel for making plastic moulds. Plastic Mould steel is mainly used in pre-hardened conditions; which enables the customer to directly use the steel by only elic cutting it. The particular advantages of this grade of steel is that it saves hardening after machining and can be used for very large dimensions in as-supplied condition.

The growing demands on shape, function, surface finish, decorativeness, aestheties and plastic mould and the steel it is made of to be of top quality. Therefore, manufacturers of operation period that will remain their high standard quality on a continuous basis.

EQUIVALENT GRADES

| AMERICAN (AISI) | DIN (W.Nr) | CODE |

|---|---|---|

| P-20 | 1.2311 | 40CrMnMo7 |

| P-20+Ni | 1.2738 | 40CrMnNiMo8-6-4 |

| P-20+Ni HH | 1.2738 HH | 40CrMnNiMo8-6-4 / VR 400 |

| 420 | 1.2083 | x42Cr13 |

CHEMICAL COMPOSITION

| C | Si | Mn | P | S | Cr | Mo | Ni | |

|---|---|---|---|---|---|---|---|---|

| P-20 | 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | 0.35 max | 0.35 max | 1.80-2.10 | 0.15-0.25 | - |

| P-20+Ni | 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | 0.35 max | 0.35 max | 1.80-2.10 | 0.15-0.25 | 0.90-1.20 |

| P-20+Ni HH | 0.27-0.30 | 0.03 | 1.50-1.60 | 0.010 | 0.001 | 1.20-1.40 | 0.45-0.60 | 1.05-1.20 |

| 420 | 0.38-0.45 | <1.00 | <1.00 | 0.03 | 0.03 | 12.50-14.50 | - | - |

APPLICATIONS

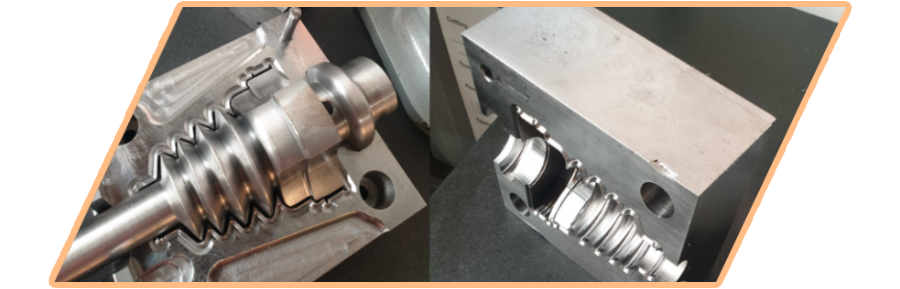

Moulds for Plastic Products

Mould Inserts

Mould cores exposed to high flexural stresses

Extruder Screws

Highly Stressed component in aeronautical engineering

High Speed Steels is being offered in conventional as well as ESR route. With Continuous improvements and research in tool steels, there is an invent of HSS produced by power metallurgy. This offers combination of unique properties :- Higher Toughness - Higher Wear Resistance - Higher Hardness - Higher Hot Hardness.

1. Excellent thermal conductivity.

2. Excellent Machinability & polishability.

3. Dimensional Stability.

4. Uniform and High Core Hardness.

5. Corrosion Resistance.

6. High Wear Resistance

Moulds made of these steels also offer very good repair weldability and they require only little maintenance and upkeep, while the properties remain the same throughout the entire service life of the mould. For all, this means high service life quantities and low mould costs per unit.