EQUIVALENT GRADES

| AMERICAN (AISI) | DIN (W.Nr) | CODE | JAPNESE (JIS) |

|---|---|---|---|

| M-2 | 1.3343 | HS6-5-2 | SKH51 |

| M-35 | 1.3243 | HS6-2-5-5 | SKH55 |

| M-42 | 1.3247 | HS2-10-1-8 | SKH59 |

| T-1 | 1.3355 | HS18-4-1 | SKH2 |

CHEMICAL COMPOSITION

| C | Si | Mn | P | S | Cr | Mo | V | W | Co | Ni | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| M-2 | 0.78-0.88 | 0.20-0.40 | 0.20-0.40 | - | - | 3.75-4.50 | 4.50-5.50 | 1.60-2.20 | 5.50-6.75 | - | - |

| M-35 | 0.85-0.95 | 0.40 max | 0.40 max | - | - | 3.75-4.50 | 4.50-5.25 | 1.75-2.15 | 6.00-6.75 | 4.60-5.20 | 0.40 max |

| M-42 | 1.05-1.15 | 0.15-0.65 | 0.15-0.65 | - | - | 3.50-4.25 | 9.00-10.00 | 0.95-1.35 | 1.15-1.85 | 7.75-8.75 | - |

| T-1 | 0.65-0.75 | 0.20-0.40 | 0.20-0.40 | - | - | 3.75-4.50 | - | 0.90-1.30 | 17.25-18.75 | - | - |

The term High Speed Steel was derived from the fact that it is capable of cutting metal at a much higher rate than carbon tool steel and continues to cut and retain its hardness even when the point of the tool is heated to a low red temperature. High working hardness-high-speed tools steels can be hardened to 62-67 HRC. High Speed Steel can be bifurcated on the basis of the alloting elements, even though their applications remain quite.

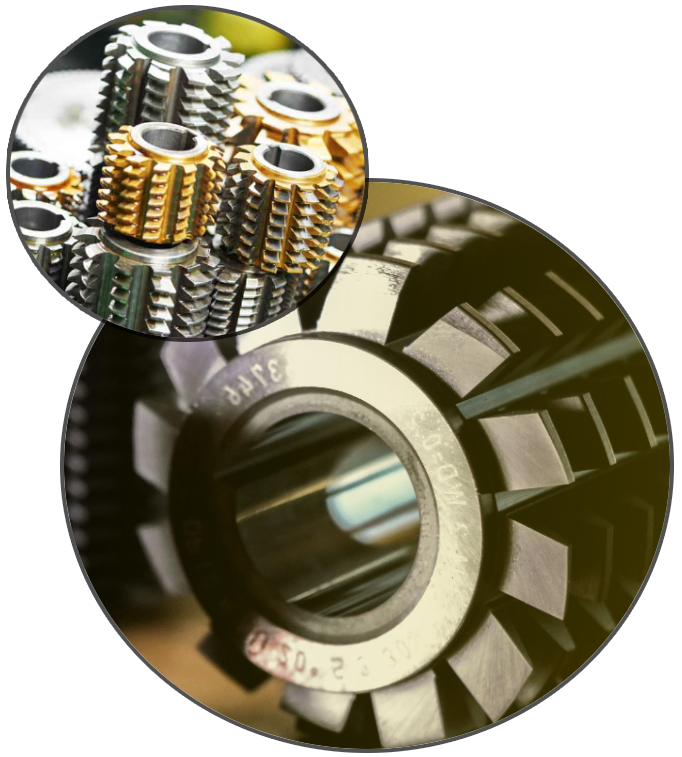

MOLYBDENUM - TUNGSTEN BASED HIGH SPEED STEELS

APPLICATIONS

TURNING TOOLS

PROFILE CUTTING TOOLS

SLOTTING TOOLS

TAPS

TWIST DRILLS

LATHE TOOLS

SAWS

HOBS

CHASERS

BROACHING TOOLS

REAMERS

High Speed Steels is being offered in conventional as well as ESR route. With Continuous improvements and research in tool steels, there is an invent of HSS produced by power metallurgy. This offers combination of unique properties :- Higher Toughness - Higher Wear Resistance - Higher Hardness - Higher Hot Hardness.

1. High Speed Steel is that it provides for predictable, improves performance. Qualities is High Speed Steels offer higher bend strength that any other cutting materials, which provides better cutting resistance to edge chipping, extending cutting depth, i.e. fewer cuts: increased feed per tooth.

2. It can maintain high hardness at service temperatures as well.

3. High Wear Resistance.

The advantages of using powder metallurgy, High Speed Steel is it provides prolonged tool life, makes tool life predictable, improves performance.